SHAH ALAM, Jan 23 — The Ministry of International Trade and Industry (MITI) through its agency, the Malaysia Automotive, Robotics and IoT Institute (MARii), aims to achieve zero foreign labour utilisation in the local automotive industry by year-end.

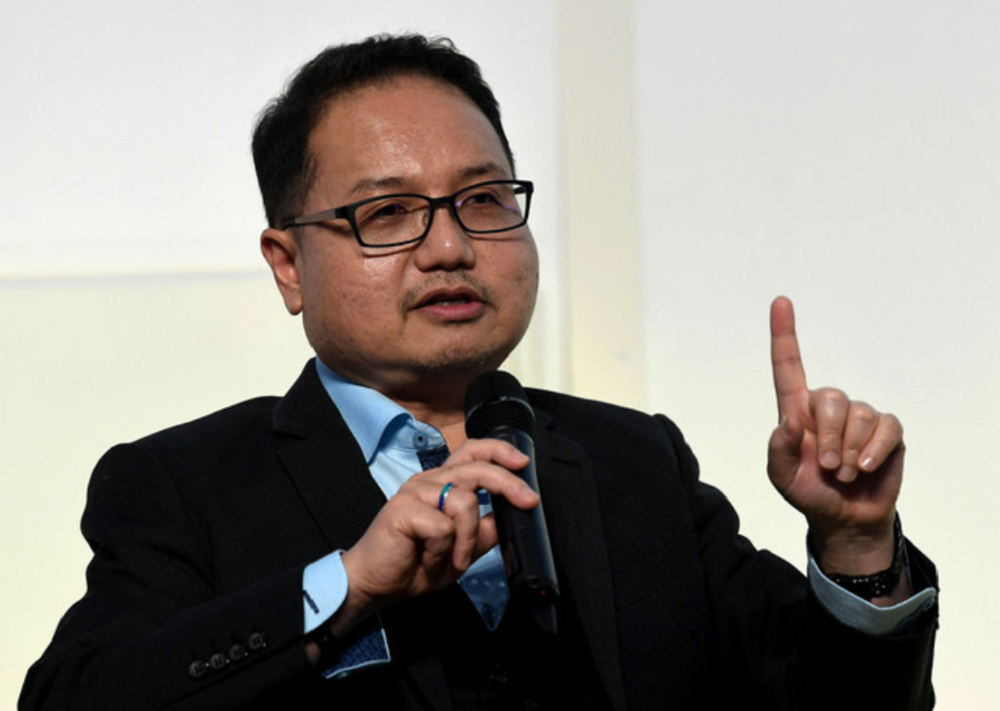

MARii chief executive officer Datuk Madani Sahari said this would make more jobs available for the locals.

“The 70,000 vacancies created from the retrenchment of foreign workers in the automotive industry will be filled by the locals.

“We have Industry-led Professional Certification training programme to train Sijil Pelajaran Malaysia certificate holders for six months, comprising one month of classroom training and five months on-the-job training, and once they have completed it, they can continue working with the vendors,” he said.

He told reporters this after signing a memorandum of agreement (MoA) with Victorious Step Sdn Bhd (VStep) here today.

Madani said for a start, Perusahaan Otomobil Kedua Sdn Bhd (Perodua) and Proton Holdings Bhd (Proton) has agreed to retrench 40,000 foreign workers in 200 tier 1 vendors this year.

Currently, foreign workers constitute 70,000 of the 220,000 tier 1 and tier 2 workers in the automotive industry.

He said efforts to reduce foreign worker dependency have been ongoing since 2014 and as of last year, 32,000 foreign workers have been replaced by locals.

Asked on the impact cost of the exercise, Madani said based on MARii’s cost-benefit analysis, the move would not increase costs for vendors.

He said unlike foreign workers that have to return to their country of origin once their term expires, local workers would remain in the country and this would reduce employers’ retraining cost.

“Furthermore, there are also costs in terms of foreign workers levy, passport and other related costs involving foreign workers that has to be borne by the employers,” he said, adding that overall, it would be cheaper to hire local workers compared to foreign workers.

On the MoA, Madani said it would help VStep — a local parts and components supplier specialising in injection moulding — to embark on a value-added transformation through the deployment of smart automation technology. — Bernama